Years into the economic recovery, hiring remains slow. Many businesses learned to do more with less during the recession, so they don't need to bring on as many people now.

These new efficiencies have led to what economists call "labor displacement," which is taking place around the country. One business in Rockville, Md., is doing the same amount of work with half its original staff.

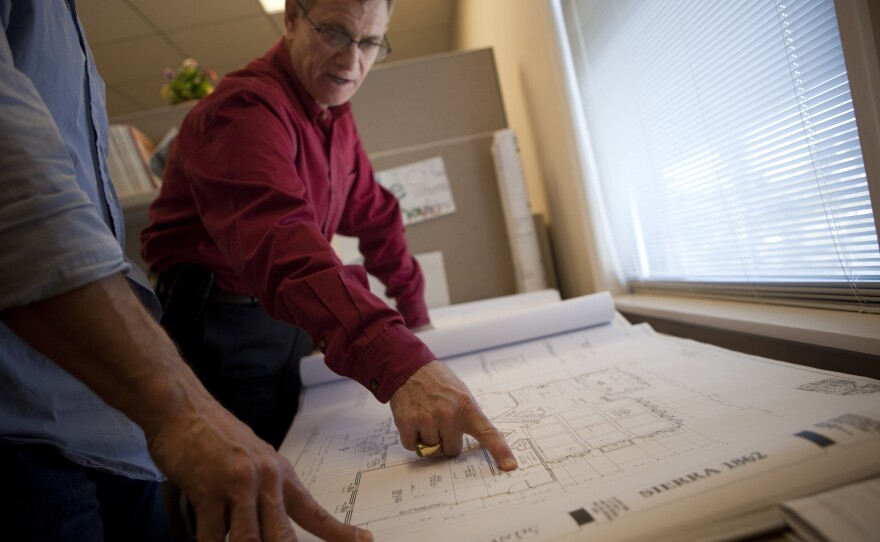

Two things are noticeably absent from the offices of Mid-Atlantic Builders: people and paper.

John Lavery, vice president of sales for the residential builder, keeps a relic in his office of the company's recent past: a binder heftier than a phone book that's filled with sketches and floor plan options of all the homes the company builds.

"Each home had sometimes up to 25 different versions of the fronts that they could choose from. And then literally hundreds of layouts," Lavery says.

There are millions of permutations and combinations possible for the company's customizable homes. The paper-based systems had been confusing and fraught with potential for error, miscommunication and logistical snags.

But a few years ago, the company automated everything. Now, customers click and drag to design their floor plans. Those changes update in a single digital file, which in turn syncs up with the design, procurement and billing systems. Lavery says workers no longer wrestle with muddy blueprints or misplace orders for windows. And automation has made it possible for each worker to do more.

"I would say it doubles their efficiency," Lavery says.

Before the recession, Mid-Atlantic Builders employed 75 people. That fell to a low of 22 because of the housing market collapse. The company resumed hiring again with the recent uptick in business and by next year plans to build almost as many homes as it did at its peak -- but with half the staff it once employed.

Besides the automation, the company's executive vice president, Stephen Paul, says he's found other ways to cut time and waste. In the past, he says, he might have had a team of employees on-site. Now, he needs only one.

"Back in the day, when we'd get more and more houses, we'd just get more and more people, we'd be throwing bodies at the problem," Paul says.

He's testing a new strategy to build a large luxury home: He's contracting out the building of the frame, the walls, and windows to a bigger company that builds the home in pieces, then assembles it on-site.

Jim Barbes, the area manager of that bigger firm, 84 Lumber, says more builders are turning to his company to essentially prefabricate their homes.

"In a sense we kind of become a virtual factory," Barbes says. "We're able to take it from design all the way to a total structure."

Outsourcing shaves weeks off building time and makes the process less dependent on weather. It also reduces headaches. Instead of hiring five or six contractors from roofers to drywall people and window installers, Mid-Atlantic Builders deals with just one.

Paul says the changes have allowed him to go after a different kind of talent. Now he recruits people like Christian Cerria, a recent University of Maryland graduate.

Cerria is not only young; he did a stint with Apple and pushed Mid-Atlantic Builders to use iPads and iPhones to manage a project without shuttling blueprints back and forth. Technical know-how like this makes it easier to coordinate the complex dance between the arrival of supplies and workmen, which cuts down on both mistakes and cost.

Timing is everything, Cerria says.

When everything arrives at just the right moment you don't have workers standing around waiting for something to do. And you also don't have a house full of appliances inviting theft. Paul says there's little he misses about the old way of doing business.

"It's a lot of work to retool a company," he says. "To see the computer system you saw, that took thousands of hours to do that, but once you get past the pain, it's a powerful tool. Very powerful."

And now, he says, it's paying off.

Copyright 2013 NPR. To see more, visit www.npr.org.