S1: A work trip is coming up this spring , so. Okay.

S2: Okay. Okay. Enough.

S1: Enough.

S2: This is cool. Oh. Welcome to hope it survived. I thought it was going to be in the floor and shredded into a lot of little pieces by now. It's awesome. Yeah , it's still up.

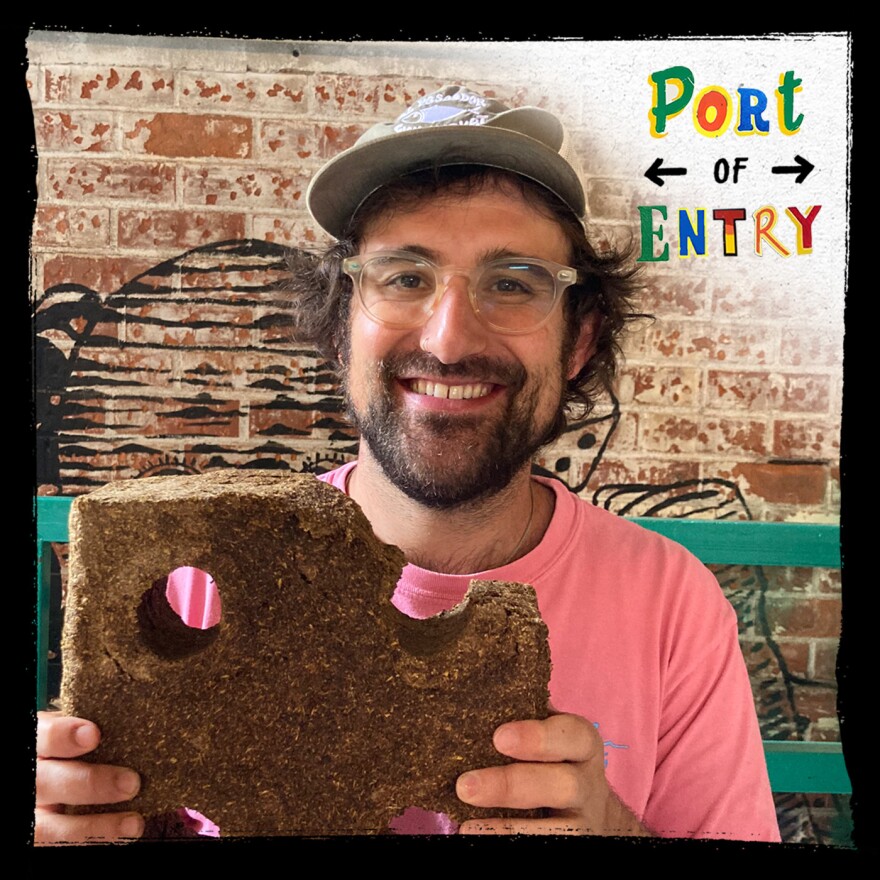

S3: Earlier last year , our producer , Julio headed to San Diego's Beach Aquarium to meet with Ethan Lilienthal , an emerging bio designer and architect. ETA wanted to show us one of his proofs of concept. A Birch Aquarium staffer escorted them through the different parts of the aquarium to the exhibition hall where Ito's piece was hanging.

S2: So that's the piece. That's the piece. So that's a made entirely 100% out of kelp or seaweed. So all the seaweed was collected , I guess , within a mile radius from here. Two miles.

S3: It was showing Julio a lamp made out of kelp.

S2: But instead of using rice , paper and bamboo and a form of like rice paste that the Japanese have traditionally used , this one uses nothing but seaweed.

S3: And if Ito's last name sounds familiar , it's because he also happens to be Alan's younger sibling.

S4: Yeah , he's second in the Lilly litter and the quirky scientist of the family.

S3: Ita is trying to find better and more sustainable ways to build.

S4: He's the founder of Casa Tamarindo , an architectural startup specializing in bio design and bio architecture in the Baja San Diego region.

S3: Its scope was an oblong sphere about 90cm in diameter , that resembled a Japanese paper lamp.

S2: I use the blades of the plant of the seaweed , and I process them in a certain way to create like sheets out of it , that then I can form into whatever shape I want , and then to make it all stick together , I use a paste or like a glue made out of my leftover seaweed that , um , yeah , works basically as a paste. And the reason all this works is because of a magical quality or ingredient seaweed has , which is alginate.

S4: Alginate is primarily derived from various types of seaweeds , such as giant kelp. Its versatile nature makes it a key ingredient in numerous products with a wide range of uses , from thickening toothpaste and ice cream to insulating fabrics , among many others.

S2: So that's like the sticky stuff that if you leave , if you see seaweed on the beach that's washed up and it starts to dry , that when you grab it , it's like sticky. That is the alginate.

S4: The discovery and development of alginate has been one of the most impactful of our industrial age.

S2: So I kind of use that to my advantage by controlling it in a certain way. So it acts as a glue.

S3: In the scalp lamp isn't exactly reinventing the wheel , but it is a creative way to tap into the versatility of that biomaterial , all with the goal of finding new ways to substitute conventional materials that pollute the planet.

S4: And the cool thing is , kelp isn't the only thing Etah has been experimenting with. He's going down the biomaterials rabbit hole , exploring other materials in the hopes that one of them proves to be the next alginate.

S3: If this is the first time you are tuning in , we are showcasing people with out-of-the-box solutions to everyday problems.

S4: This season is all about visionaries and shapers of the borderlands. Today we're picking up where we left off last year and diving into the third part of our series.

S3: The Planetary Scale Part three. Editors.

S4: Editors. Quest for the Holy Grail.

S3: Stay tuned.

S4: From KPBS. This is Port of Entry.

S3: Where we tell cross-border stories that connect us.

S4: I'm Alan Lilienthal.

S3: And I'm Natalie Gonzalez. You are listening to Port of Entry.

S4: We started this short series thinking about the impact we have on the environment on a planetary scale. How what we do and what we make not only affect our immediate environment , but the planet and future generations. We'll leave parts one and two in the description.

S3: ETA had been orbiting around those first two installments of this planetary scale series. He was instrumental in helping us reach out to people who share his views , and has been patiently waiting for his moment in the spotlight.

S4: ETA invited us to one of his workshops called vernacular , where he was showcasing this new bio material he's been working on , one he thinks could be as impactful as alginate.

S3: When our producer Giulio got there , workshop participants were making all sorts of shapes with samples of his biomaterial.

S4: It looked like everyone was playing with lumpy Play-Doh.

S5: So this material , when I get it from the brewery , is like a wet oat. Think about it like like overnight oats. That's kind of how it's given to me. And I pass it through a process that I developed , where it goes from.

S2: Blending it and turning it into like a powder to kind of turning it into a mush , but kind of trying to make it into as much of a smoothie as possible.

S4: Etta had a display of different sculptures made from this beer based clay , including a big square brick with four holes in it that was missing a corner chunk.

S2: And through that process , I boil it for a long , long period of time. And as it boils , a chemical reaction happens where it becomes its own glue. So this material kind of works like a ceramic. It can be treated like clay , but it dries like wood , and it's completely natural byproduct of the brewery making process.

S3: Anita's big idea finding a sustainable alternative to wood.

S2: I think how I see it as like anything that you can do with wood , plus more. But I want to do I want to start like 3D printing objects out of it , like extruding. You can see and see.

S3: People were attentive and passing around some of itas samples.

S2: Like if you want to do like a floor , this can be like a natural board that you come on. It's like a pace that you do on the floor. You can make disposable plates out of this easily. I would have like a heat press and that would be super quick. If I was doing a house , I would probably make it would be similar to how you dry Adobe bricks. You have to dry them and maybe like flip them around again if you're perfect conditions. Is windy , sunny weather where this material is way better than any other biomaterial in the world is because most biomaterials that you'll read about are kind of like some form of agricultural waste mixed with the same type of natural binders that you have to buy separately. So that binder can be cornstarch , it can be alginate , you know , it can be carrageenan. But again , it's always like you get some agricultural waste and you introduce a glue that happens to be natural , but it's still probably produced in a factory somewhere halfway across the world. This material is different because the beer itself becomes its own glue. It's only binded by its own by itself , which makes it completely producible at home or like , you know , locally without dependent on like globalized supply chains to make it happen.

S3: Ita is thinking big. He aims to reduce dependence on wood and preventive forestation. But big ideas for big problems require big solutions and variations for that matter.

S4: ETA had an idea he wanted to try out. He had a lead in El Sawzall , about 60 miles south of the border. Our producer Julio tagged along to see what it was all about.

S2: Look at. Look at that resolution , dude. God finally gave us that 4K we were waiting on.

S4: It was a bright , sunny day with a slight overcast. The silver lining of the clouds made for a spectacular view of the Baja coastline on the way there. ETA broke down.

S2: One is you're not only designing for humans , but you're designing for all organisms , for biodiversity. On top of that , you're also seeing the building as like a living organism. So that can be as far as like how you regulate energy usage from like passive energy , how you regulate like ventilation and stuff like that to , um , how you can utilize having green roof that is supporting a certain amount of biodiversity. But that green roof is also helping you in terms of a your energy cost and creating the ideal like thermal space for the inhabitants of the building.

S3: The concept of a building as a living organism is still mostly confined to the academic sphere.

S4: What constrains bio architecture from flourishing outside the lab is the same thing plaguing the construction world , something we touched on in parts one and two of this planetary scale series.

S2: I would say architecture historically has always been a process of extraction. And then you like extract resources , you enter them into cement or whatever. So that's kind of how I would see bio architecture differentiating itself from the more conventional ways of doing stuff.

S3: It stumbled into this approach during his days as an artist who wanted to do something about climate change.

S2: Specifically , I think with this biodiversity , by how much we're just destroying nature in just like such a thoughtless way. Not even that.

S3: Which brought him to an inflection point.

S2: I think as an artist , I started painting about these issues and I'm like , wait , the materials themselves are the problem. I need to make my own materials. And then I started getting really into the bio material space , which again , in many ways is like the material aspect of this bio architecture. We're talking about that. It's like how you can grow your materials instead of having it be a purely extractive model of material like creation.

S3: Julio and Etta made it to eat us. First up.

S4: It's a lumber mill that makes wooden furniture. Etta had an interesting idea he was hoping to test out. He wanted to incorporate the sawdust from their operation into the material he had been developing with.

S6: I used a tipo de maquina. Podemos utilizar para reducir el espacio y hacer negocio.

S4: Jorge Fierro , the lumber mills quality control manager , explained that the sawdust was taking over the whole shop and needed a way to best manage the waste.

S3: His boss brought a press from overseas that compresses the sawdust with thousands of pounds of force into bricks , hoping to make some sort of business out of them.

S6: Para para el bloque para una tenemos de mandar. Ahorita del este se puede ser este material. Qué Sebastian cuando buscando la manera de cu alguien se lost.

S4: Unfortunately Jorge todos there still isn't any real demand for the sawdust Briggs beyond using them as fire starters for Katrina's Kiriko. Some folks have used the Briggs for basic gardening hacks. Others have tried combining them with clay to make walls and structures , though unsuccessfully.

S3: George said the main problem George pointed out , is humidity.

S6: A alguien hacer Como Como blocks para hacer barradas. Pero por el la question de la comida no no por el tipo del cimento. La tene o el barro cu la teens cu poner pues absorb el agua. As they expand.

S3: They saw those bricks disintegrate as soon as they touch any moisture. But Itta believes he might have a solution.

S6: Y lo podemos.

S4: He mentioned the bare clay to Jorge. Ito thinks that mixing the sawdust with it may fix the humidity issue Charmander.

S6: La maquina de la la prensa de la Serena Como funciona.

S3: After a quick demonstration of the press , Cauchy handed some samples to ETA and they made their way to their second stop , ETA's house. Once inside , he walked to the porch where a couple of white paint buckets were sitting.

S4: He opened one , revealing a batch of his thick brown beer waste that resembled mole paste , and released a pungent odor.

S2: This one's a little funkier because it's been sitting out for a while , and in this scenario , I would love to mix this with the acid rain , but I don't think their machine would allow it. That's the problem because their machine seems to be pretty sensitive to like certain stuff. So because of that , it. Yeah , I think I would probably just do this more manually for now and then eventually maybe go bigger , better this way. Right now I'm kind of looking at more for like sculptures or like anything you would do out of clay. You could do it with this.

S3: Even if you splendor at the lumber mill didn't pan out the way he intended , he wasn't deterred by the no hitter , is determined to develop his material.

S4: The day was winding down. It was time for them to head back. Julio wanted to see how he put together a batch and where he picked up the material.

S3: But before that , they had some office hours north of the border with an old acquaintance of Itta.

S4: Unaware of this meeting , Etta was thrilled to discover Julio set up time with one of the most forward thinking minds in the sustainability industry.

S3: Doctor Stephen Mayfield of Al Genesis Labs. Stephen.

S7: Stephen. I am Julio. Nice to meet you.

S2: Nice to see you again. We met like seven years ago.

S3: Ita clearly couldn't contain his excitement.

S4: Yep , that happens a lot.

S7: I don't know if you remember that me and some friends called you for some advice on growing out of the algae. Yeah. Come My name for. Uh , what's it called for ? Cocktail parties. Oh , okay. And we met because it was , uh , Tory and Leslie. They're up in Humboldt now , having a big seaweed farm.

S4: Doctor Mayfield co-founded the California Center for Algae Biotechnology at UC San Diego , where one of his focuses was using algae to make everyday products like flip flops and surfboards , among many other things.

S3: These days , he runs Genesis Labs. There he produces biodegradable plastics , foams and other materials that make it into everyday products.

S4: He took Julio Anita on a tour of his lab.

S8: And run it here. These are. That's a condenser. Okay , I won't give you the wrong. I'll show you one of them in a second.

S3: The left was a maze of heavy machinery and chemistry equipment lining the halls and rooms.

S8: Anyway , so in this lab , what we're doing is raw materials in. Convert some of those raw materials to polyols. A polyolefin isocyanate makes a TPU by TPU.

S4: He means thermoplastic Polyurethane. Pretty much your conventional malleable plastic used in shoe soles.

S8: Right ? So all polyurethanes are composed of about anywheres between 50 and 75% polyols.

S3: As they made their way through the different sections of the lab , samples of foams with labels were all over the shelves of the desks.

S4: Each foam had a different label denoting its characteristics.

S7: Once you get. A.

S8: A. Poly.

S7: Poly.

S8: All we had to convert it into a foam and a foam. Again , you can make all kinds of stuff with this thing. You can make shoes , you can make flip flops , you can make seat cushions.

S3:

S8: The the big commercial machines that make these things are like an industrial ice cream blender. Right. They take two things together. They've got a high speed head and they squirt it into a cup.

S4: The two ingredients being a poly oil and an isocyanate.

S8: And then you're going to get a foam out of it. And those foams can be all over the place. And seeing if we can get a hard one here.

S3: Doctor Mayfield shuffled through the samples on the desk next to the machine. He passed them around to Julio and Etta. Its face lit. Up.

S8: Up. Sometimes they fail , right. This is a formulation that just didn't work. You're aiming for something like this , something that's got nice rebound , whatever. But occasionally you mix the ingredients and they just don't work and these things collapse.

S4: He said these algae based materials are kind of like butter , eggs and flour.

S8: They're raw materials , but what you make out of them , that's the formulation part of it. Because if you give flour and eggs to one guy , you might make a cake , somebody else might make pasta. You can make all kinds of stuff with it. Right. Exactly the same thing in polyurethanes. You got a poly oil and you got an isocyanate. Then you got a bunch of other ingredients you can put in , you can put in detergents , you can put in cross linkers , all kinds of things. And from that you can get amazing different thing. This is these are ones we're trying to make a super lightweight foam seat cushion. And what you're aiming for is something like this.

S4: Holding what looked like a run of the mill , cushion like material with the texture of slightly denser sponge cake , eat that inspected the foam with curiosity. Something was definitely ticking inside his head.

S8: Something that's pretty lightweight and has a pretty good rebound. And you want these things to be super light , right ? But occasionally you get stuff like this.

S3: Doctor Mayfield then passed a denser foam that almost felt like rubber with the appearance of lumpy cottage cheese.

S4: Good old trial and error. And it's amazing to see that out of all of that , a shoe comes out and then eventually bio degrades instead of sticking around forever.

S3: But you're probably wondering , like we are , if something is meant to biodegrade , it's adorable.

S9: You can actually throw these in your washing machine and wash them. They'll last 3 or 4 years.

S4:

S8: All shoes a braid. Anybody who's walking around is losing part of their shoe. If you look at the bottom of any one of these shoes , the more you worn them out of braids.

S3: You can measure this. Doctor Mayfield has machines that do just that.

S8: So if we take ours and we take a petroleum and put them on that machine , we last about 1.5% longer than a petroleum shoe does. We put them on a robot. We did 100,000 steps with a robot. Our hours lost very little material. We happen to test them against any of the big brands. They lost more material than us. So from an abrasion sense , we're more durable than they are. But if you take one of their shoes and put it into compost , it'll be here in 100 years. Some of these shoes will be around 200 or 300 years from now.

S3: Seeing the process unfold clearly in front of him. Etta could tell what the key step was , chemically speaking.

S7: And to make it biodegrade. You're basically wanting to introduce it so certain microorganisms can break those cross-links that you you guys are creating. Exactly.

S8: Exactly. That's it. Exactly. If a bond exists in nature , then there's a microorganism that can eat it.

S4: And check it out. Here's the kicker these biodegradable sneakers might actually be good for the planet. Doctor Mayfield pointed to some potted sunflowers in the back of the room.

S8: So when ours is biodegradable , is it creating microplastics ? What we did was we took a shoe and a phone case made from our material , ground them into microplastics , mix them with compost , and then watched over 200 days as ours disappeared.

S3: Some of the flowerpots just had soil , while others contain ground up algae. Microplastics , the ones labeled with his material , looked slightly taller.

S8: We were shocked when our stuff grew so much better than the control. We think we know the reason for that. Isocyanate has got a nitrogen in it. And so when you form a polyurethane bond , there's one nitrogen. So when you break that down , you get that nitrogen release back into the soil.

S3: And if you know anything about gardening like I do , nitrogen is one of the main ingredients in fertilizer.

S4: You just learned that. Yeah.

S3: Yeah.

S8: So what does this look like ? This looks like no nitrogen plus nitrogen fertilizer.

S3: So the algae microplastics weren't just disappearing. They were feeding the plants.

S4: Seeing the material come full circle from creation to degradation left an impression on ITA. But Julian Ito were left wondering. Was it scalable and commercially viable ? According to Doctor Mayfield , their product is only 25 to 35% more expensive than mainstream petroleum based materials.

S8: So the shoe brands , when we talk to them , they're like , we'll make 10,000 or we'll make 50,000 shoes with you. But if you really want to be in one of our big markets where we're making 1 million or 10 million shoes , you got to be within 25% of the cost of petroleum. But we can get there with those volumes. We've already calculated.

S4: We know their successes resonated throughout the chemical industry.

S3: Doctor Mayfield said they have received interest from a big chemical company. He recalled the conversation with an executive from one of those companies.

S8: Oh , we'll help you only when we can. Call us anytime you want. You know , we'll get our engineers to help you guys , because when you're successful , and we really hope you are , we're going to buy you. And I'm like , okay. And then go. And don't worry , it'll have a lot of zeros on that. You'll be super happy. Okay great. And we're getting closer. So we keep the conversations going with them now. Their competitors now know that we have moved far enough along , that now their competitors are starting to call us.

S10: That's a good place to be.

S4: It was truly wowed at the news of Doctor Mayfield's milestone. His material checked all the boxes for being truly sustainable.

S3: Completely circular.

S4: And knowing how high the standards are. The fact that he was impressed says a lot.

S3: You are listening to Port of Entry , and Coolio followed Doctor Mayfield back to his office.

S4: What had been brewing Anita's head during the tour finally made its way out.

S2: And what I discovered is basically the beer waves. I get this fine grains from the brewery. I'm actually going to call Strauss after this to pick them up , and by boiling it and then just messing with its pH , increasing its pH with like adding sodas and stuff like that , that by increasing its pH , you're destroying its like cellular structure. So you turn it into a like into a muck , and then it creates its own binder. And then I can read , like , literally just by boiling it. And of course , there's a recipe , there's an art form to it , but I can make pieces that are like , I actually have like a little thin thing in my car that it's like as hard as it's a putty , it's like a ceramic clay that you can work with it , like if it was a ceramic , and then it dries into a piece of wood , you know , like into like a piece of wood. And it's super lightweight. Like you can use it for like , wall panels.

S8:

S2: Okay , I would call it the same thing as would if you put a piece of wood outside , it's going to absorb it. You'd have to put some beeswax at the bare minimum , but it works very similar to wood. So right now I'm enjoying just going deep into the beer because yeah , you can get it anywhere in the world at a consistent , quality weekly.

S8: If you can get a waste stream. That's what we did with our algae. That's why we can afford that stuff. These guys were making omega threes and they didn't know what to do with it. And we're like. Please.

S2: Please.

S8: We'll take it. If it's got a double bond in it it's reactive. We can use it. And now the same is true for hemp oil.

S3: Ita then had to shoot his shot.

S2: So I don't know. I'm kind of like approaching it from a more of like I guess artistic and architectural because I'm not ready to have like a tech company , you know. But yeah , that's kind of oh , if not another day , I'll come and show you some samples just to get some feedback from you. Yeah , yeah. I'll give I don't know if I can give you beer shoes , but I'll see what I can bring back a. Beer.

S8: Beer. Table.

S2: Table. Okay.

S8: Picnic tables.

S2: Let's do that. Let's do that. Yeah. We can play beer pong on it. Exactly.

S4: Their time at Al Genesis was ending as Oeta had to get going to pick up that batch of beer waste. They said their goodbyes and headed to ETA's car. Julio could hear ETA's brain ticking , overstimulated by everything they just seen. ETA shared a realization.

S2: Because it's very crazy to see how he can take a simple material and transform it in so many different ways. And I think for me , when I look at it , the stuff I want to do with my own biomaterials , knowing that it's like on one end , it's very sobering to know how long of a journey it's going to be. Realistically , that's kind of part of the process. It's like the hero's journey in that regard. So like on one end , I feel like I come out of this space intimidated in a good way , like overwhelmingly excited and intimidated. And I find myself kind of with that same excitement of where I can get to with the beer material , you know ? And when I see the , say , the beer material , it's not only that , it's kind of how I want to combine it with living organisms like mushrooms , like with just different processes.

S3: It's eyes were gleaming , overtaken by the side of the road that I waited in front of him.

S2: In a way like , I see it's one of those inspirations when you see very clearly the road ahead , but you know that it's like it takes time. But leaving places like Al Genesis inspired , you're in this moment when you don't really care how long it's gonna take or you know what it takes to do it , but you're just feeling like it's possible and you're seeing it in front of your eyes. But if I'm serious about this , and I really want to make it be what I know it can be. It's good to know that there are people around that I can point to for advice and inspiration.

S4: They made their way to the brewery to pick up the beer waste , and filled in the supervisor about his intentions for it. Eat that pulled out a shovel from the back of his car.

S11: Not that much , but yeah , I don't know if you get to fill this out or I don't know what what the options are. Can I see it's coming out right now ? Yeah , but like , all that's fallen in here. So you have to dig it out anyway. That's the only way to get it. Yeah.

S3: He shoveled piles of the material into a big plastic garbage can.

S11: Especially now that I think about it. There is , um , if.

S2: You have one that's already.

S11: Done , I can just take that. Cool. And I'll just leave this for you guys. Karl Strauss brewery. What does that shovel for us ? Hey , it's to get some , but. Yeah , so we're getting some beer , so I make.

S4: It to take the waste back to our parents place , aka his lab , his storage facility. My mom really loves it. Where he would prep it for the next installment of his workshop series.

S3:

S4: Not to mention the all the great lingering smells he leaves in the kitchen for weeks.

S12: Oh my God.

S3: Ethan clearly believes he has something special. You can hear it in the way he talks about his development , but for now , it's unclear to him if this beer waste material has the legs to reach the heights that Doctor Mayfield has.

S4: But what if it did ? I believe in Julieta.

S3: What if you could replace the wood we use in so many areas like flooring or furniture with items , beer , waste , clay.

S4: It took Doctor Mayfield a whole career. Plenty of trial and error. Years of focused research and development , investors and institutional backing to get to where he is now.

S3: May not have all that , but he has the drive and patience to keep trying , the confidence to push through moments of doubt. And most importantly , he has the greatest ally an inventor can have time.

S4: This episode of Port of Entry was written and produced by Julio Cesar Ortiz Franco.

S3: Adrian Villalobos is technical producer and sound designer.

S4: This episode was edited by Elizabeth Hames and Chrissy Wynne.

S3: Lisa Jane Morissette is director of audio programming and operations.

S4: I'm Anna Lilienthal.

S3: And I'm Natalie Gonzalez.

S13: Nos vemos pronto.